Trend Products

Professional Range Tooling

The Trend Professional Range is aimed at the most demanding applications in manufacturing and the woodworking trades. Products are precision engineered to the highest standards and tolerances. For industrial applications the tooling fulfils the needs of modern routing technology, where machining performance relies on the highest possible standard of excellence. Trend industrial tools include replacement tip tooling, spiral and PCD to increase productivity, reduce down time and give an accuracy of cut throughout the tool life. Whether in industry, on-site or used by professional woodworkers, the Trend Professional Range offers the choice and performance for every application.

Trade Range Products

The Trend Trade Range is aimed at the building professional. These products are focused on increasing productivity and maximising profitability for a wide range of on-site routing and joinery applications.

Trend Modular Window System

The Trend Modular Window System has been developed for small to medium sized joinery companies, builders and developers to enable them to produce 8 different styles of timber window quickly and accurately on a spindle moulder with a low investment cost.

Each individual tool and spacer is numbered and every style of window comes complete with a wall-chart showing the steps required to manufacture a complete window. It´s as easy as making windows by numbers.

Many of the tools and spacers are common across the 8 different window styles thus making it even more cost effective when producing more than one type of window.

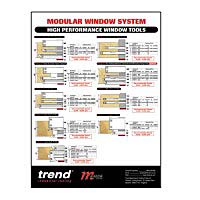

Trend Modular Window System Catalogue

Trend have a 64-page brochure on their new Modular Window System.

Also included are details on door tooling, Trend´s new Spindle moulder, surface planer and thicknesser, and other accessories for making windows and doors.

Click on the image on the right to get your catalogue.

Trend Modular Window System Article

Written by Colin Peacock – Tooling Application Engineer

The demand for timber windows has increased significantly in all sectors of construction with new build, replacement or renovation due to the ´green´ credentials of timber windows and concerns over uPVC.

To meet this demand the Modular Window System has been designed for small to medium sized joinery companies, builders and developers enabling them to produce timber windows quickly and accurately on a spindle moulder with a sliding table for a low investment cost.

With this new system the manufacture of any size of window can now be completed in 2-3 labour hours, and not the typical 6-8 hours. This gives the joinery shop the ability to respond quickly and consistently to customer requests and be able to make small quantities of windows in a very cost effective way.

The main benefit of the system is that the fence and spindle height are set once (in seconds with the supplied setting gauge). Then all of the slots, tenons and profiles on the outer frame and sash are machined in one pass without making ANY alterations to the machine. This dispenses with lengthy set-up and costly test cuts, which requires the concentration of a skilled joiner/machinist and almost invariably reduced profit margins.

All the joints on the outer frame and sash are slot and tenons but no length stops are required for all operations regardless of size, design or style. All timber sections are simply cut to the required aperture size. The individually numbered steel tools and spacers are stacked onto the spindle according to the steps shown on the supplied wallchart. This helps enormously to speed up the assembly process for each operation and changing the tools takes seconds.

All of the tooling is fitted with, mainly standard, tungsten carbide disposable inserts, giving constant diameters and profiles. Therefore all inserts are available from stock for next day delivery.

Many of the tools are used in more than one of the seven window styles, thus making it even more cost effective for making more than one type of window. So minimal extra tools are required for the new style and not a completely new set.

As the accuracy of the joint is built into the tooling dimensions, no test run is required. You can therefore produce a window including sash complete with ironmongery in under three working hours without previous knowledge of window manufacturing (but you must be fully acquainted with spindle moulder operation).

Set Fence and Spindle Height

The machine´s fence and spindle height can be set-up in seconds using the supplied setting gauge.

Slots and Tenons

Machine all the slots and tenons. Thereafter there is no need to alter the fence depth and spindle height.

Profiles

Machine all the profiles. Again there is no need to alter the fence depth and spindle height.

Clear Numbering

Each tool and spacer is uniquely numbered making it very easy to identify the right tool and set up each stack in seconds.

MWS Wallcharts

All window systems are clearly numbered with step by step instructions on wallcharts provided.

Spindle Moulder Specification

You can use the Modular Window System with any spindle moulder with the following minimum specifications:

-A sliding table (preferably flush with the machine table).

-A spindle shaft diameter of 30mm or 1-1/4 inch .

-Usable spindle shaft height of 120mm minimum.

-Recommended motor power 7.5HP 3 phase.

-A spindle speed of 3,500 – 9,000 RPM.

-A power Feed (mandatory).

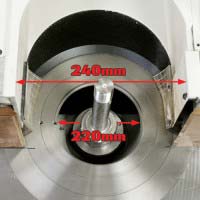

-A 220mm aperture diameter required through the machine table.

-A 240mm diameter required inside the hood and with clear vertical access.

Example of Slot & Tenon for High Performance Style Windows

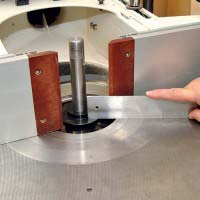

The High Performance style of window is one of the most popular. The stack for the Tenon outer frame is shown.

Example of Outer Frame Profile for High Performance Style Windows